electrical discharge machining ppt

This is when the challenge becomes real and Thesis On Electrical Discharge Machining the stakes get high. PowerPoint PPT presentation free to download.

Electrical Discharge Machining

Pdf ppt on edm grinding process Crusher South Africa.

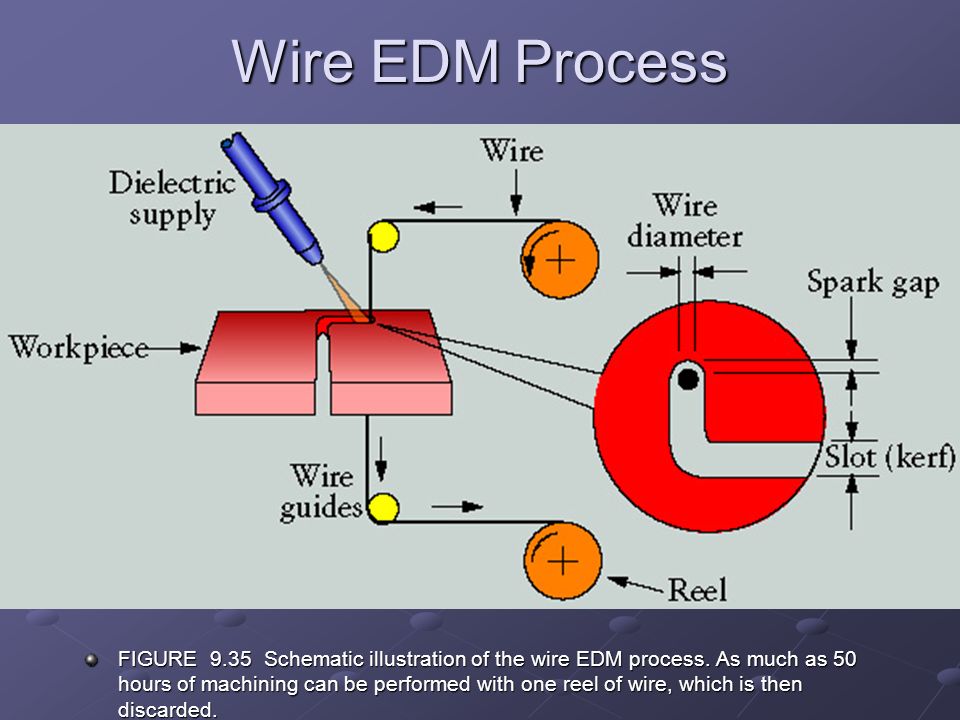

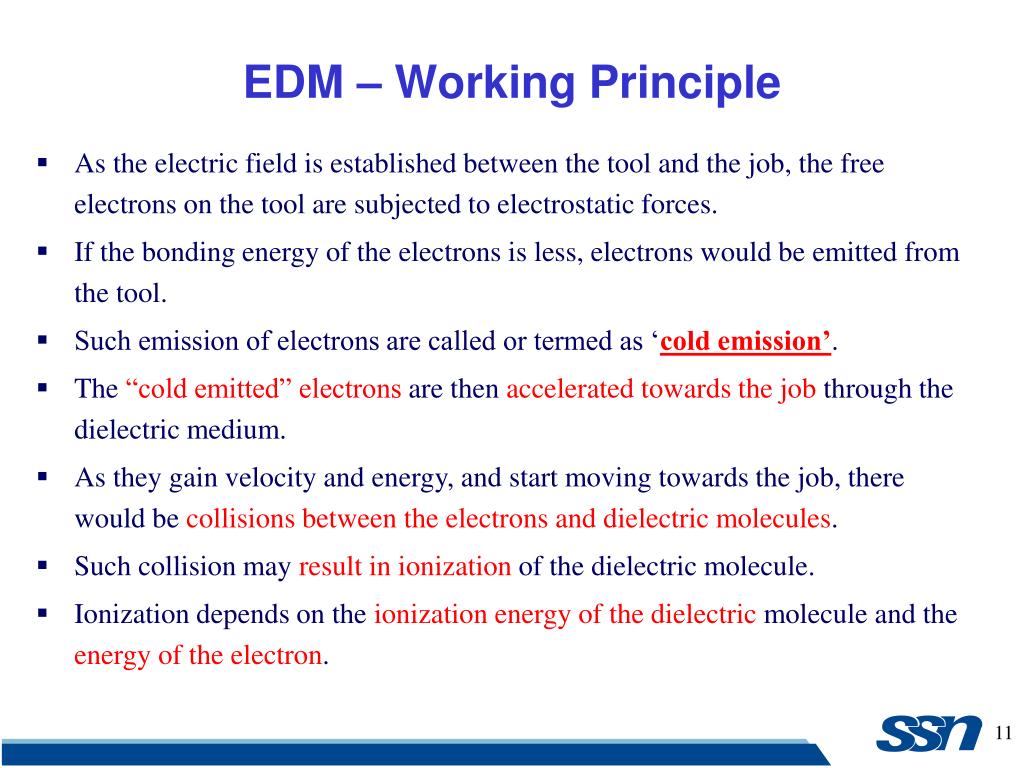

. It is a simple low maintenance clamping device primarily used as an accessory to grinders intended for precise surface grinding of very small thin parts up to large workpieces and electrical discharge machining EDM. Wire electric discharge machining 31. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid.

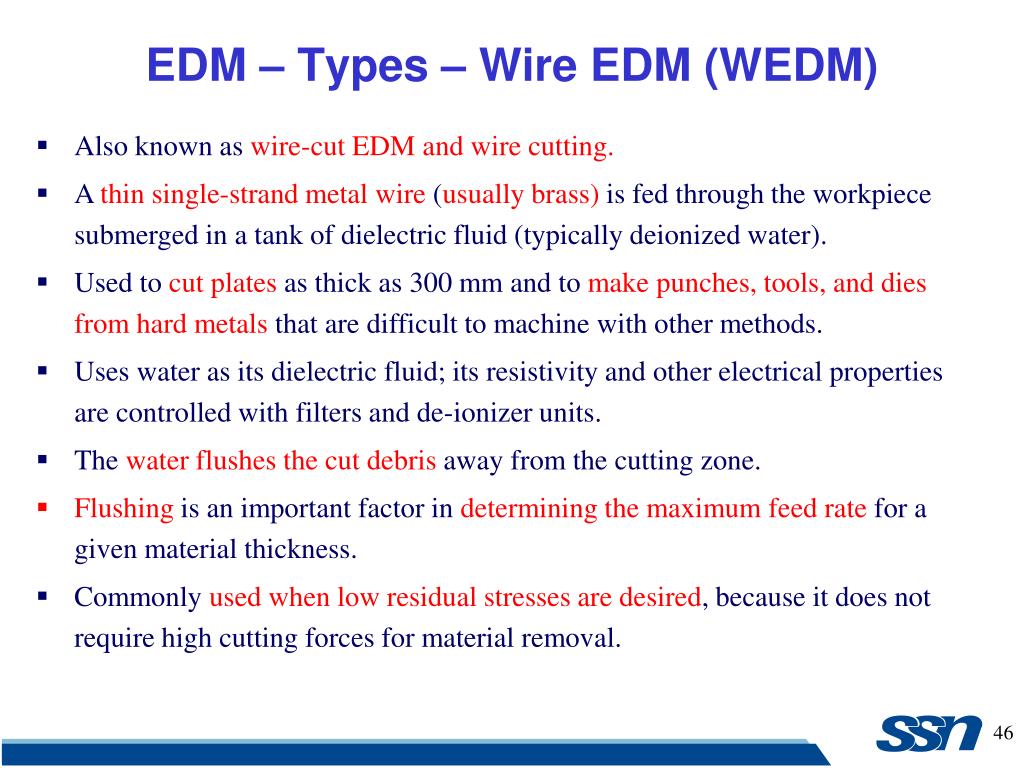

Gets from 9400 C to 17000 C Which makes the process much faster the LBM and EDM with better products EBM have limited machining because of the vacuum capacity Water Jet Machining Cut a variety of metal. The hole drilling process involves using a brass electrode tube to channel the electrical discharges onto the material. Wire-cut EDM is typically used to cut plates as thick as 300mm and to make.

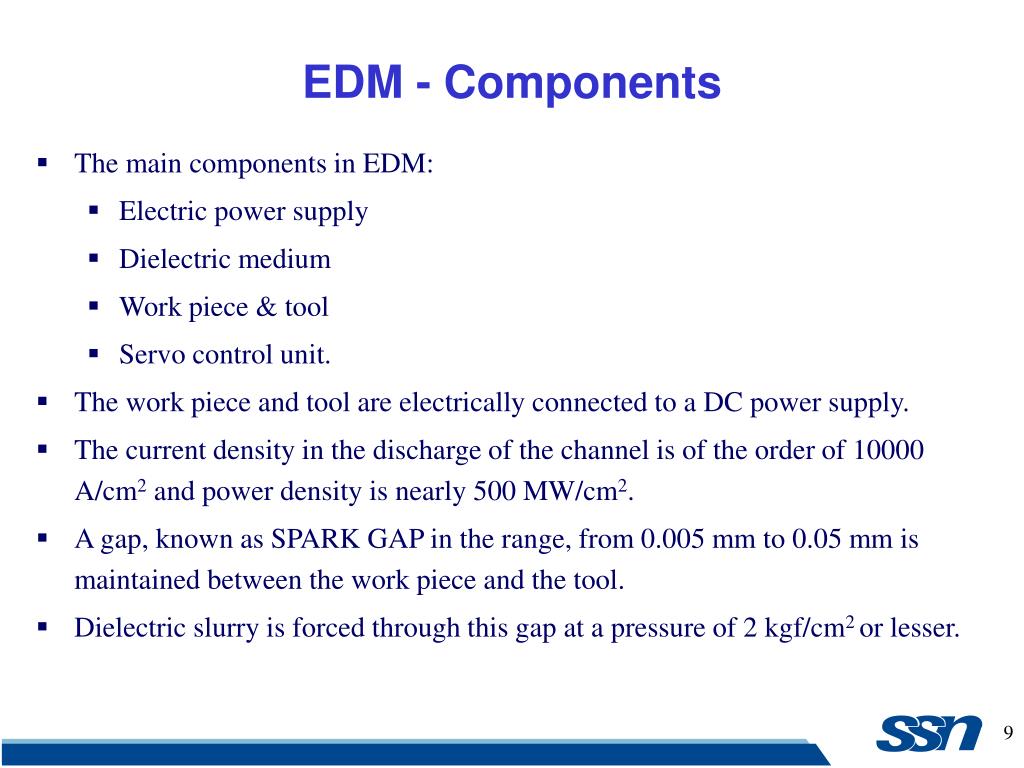

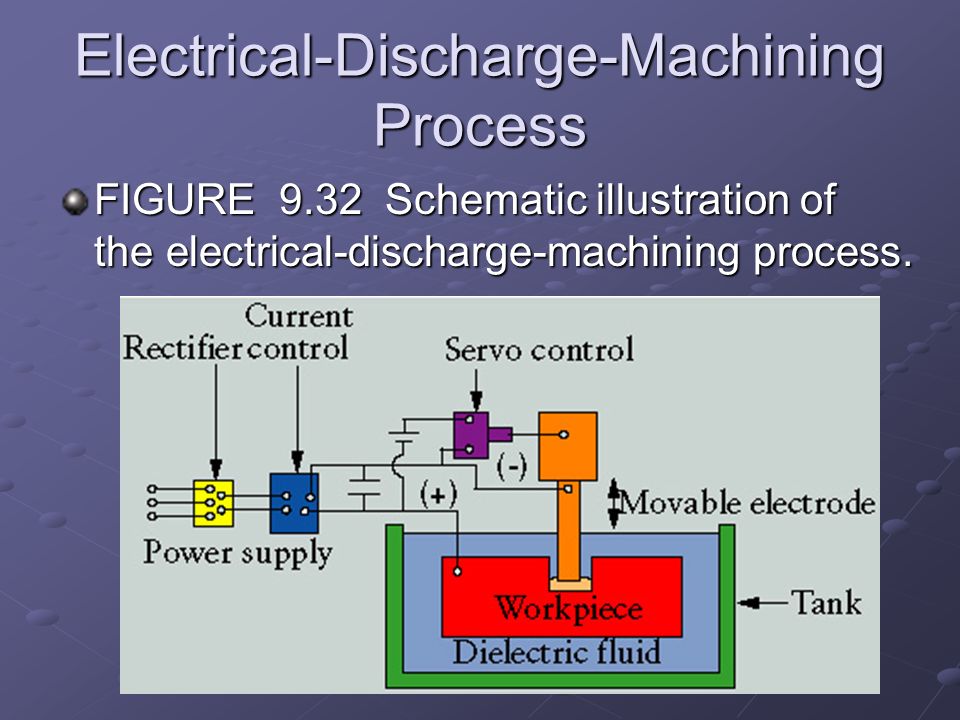

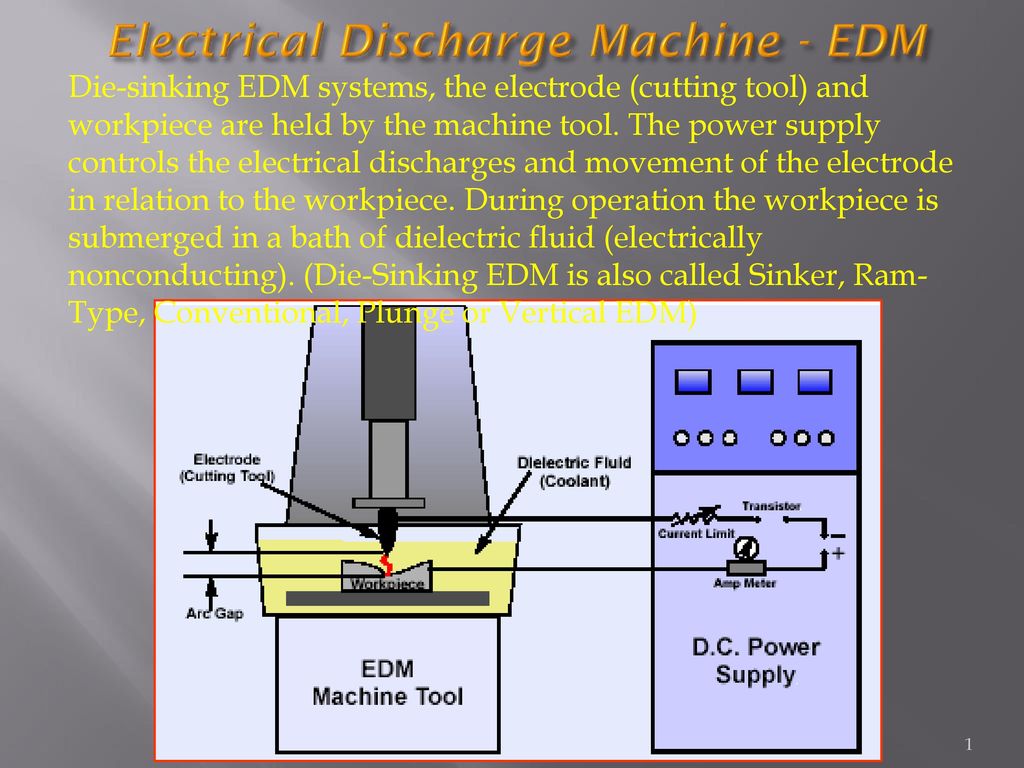

Electric Discharge Machining A schematic diagram of EDM using relaxation circuit. Electrical Discharge Machining Used on hard metals works with electrically conductive materials 3. Introduction Electro Discharge Machining EDM is an electro- thermal non-traditional machining process where electrical energy is used to generate electrical spark and material removal mainly occurs due to thermal energy of the spark.

Developed in the mid 1970s In the mid 1980s the EDM techniques were transferred to a machine tool Todayit is a viable technique that helped shape the metal working industry. Electrical Discharge Machining A spiral cavity produced by EDM using a slowly rotating electrode similar to a screw thread Examples of cavities produced by the electrical-discharge machining process using shaped electrodes. 1 Electrical Discharge Machining EDM GOPINATHG MECHANICAL.

Electrode and workpiece material vaporized. Wire Cut Edm Ppt Free PPT downloads. The EDM Process At Aero Manufacturing we use a process known as Sinker Electrical Discharge Machining.

Of advanced materials machining such as Abrasive Electrical Discharge Grinding and Abrasive Electro chemical. 1Pulse Generator Power Supply. EDM processes present several advantages for custom metal fabrication.

This helps to create holes of various small dimensions. Vaporized cloud solidifies to form EDM chip. First discovered in the early 1940s this method is frequently used in tool and die applications to create intricate shapes and challenging parts.

Electro Discharge Machining EDM is an electro-thermal non-traditional machining process where electrical energy is used to generate electrical spark and material removal mainly occurs due to thermal energy of the spark. Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness. Some students think that a college paper is a piece of cake until they actually encounter a term paper.

Machining and machine-tools 2013 Download as PDF About this page. Developed in the mid 1970s In the mid 1980s the EDM techniques were transferred to a machine tool Todayit is a viable technique that helped shape the metal working industry. Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques.

Global electrical discharge cutting machine market research report 2017 - Electrical Discharge Cutting Machine Report by Material Application and Geography Global Forecast to 2021 is a professional and in-depth research report on the worlds major regional market conditions focusing on the main regions North America Europe and Asia-Pacific and. An Explanation for the parts of Electrical Discharge Machining is as follows. International Journal of Machine Tools Manufacture 39 669-682 1999.

WHAT IS EDM. Electric Discharge Machining EDM PPT Download. In wire electrical discharge machining WEDM also known as wire-cut EDM and wire cutting a thin single-strand metal wire usually brass is fed through the workpiece submerged in a tank of dielectric fluid typically deionized water.

Material is removed from the workpiece by a series of rapidly recurring current. Electrical Terms - Merit Badge Class 1 Name. Electrical Discharge Machining Used on hard metals works with electrically conductive materials HISTORY OF EDM In1770s discovered by Joseph Priestly.

Material is removed from the workpiece by a series of rapidly recurring current. Electrical Discharge Machining EDM 2 Sometimes it is referred to as spark machining spark eroding burning die sinking or wire erosion Its a manufacturing process whereby a desired shape is obtained using electrical discharges sparks. Electric discharge machining 2.

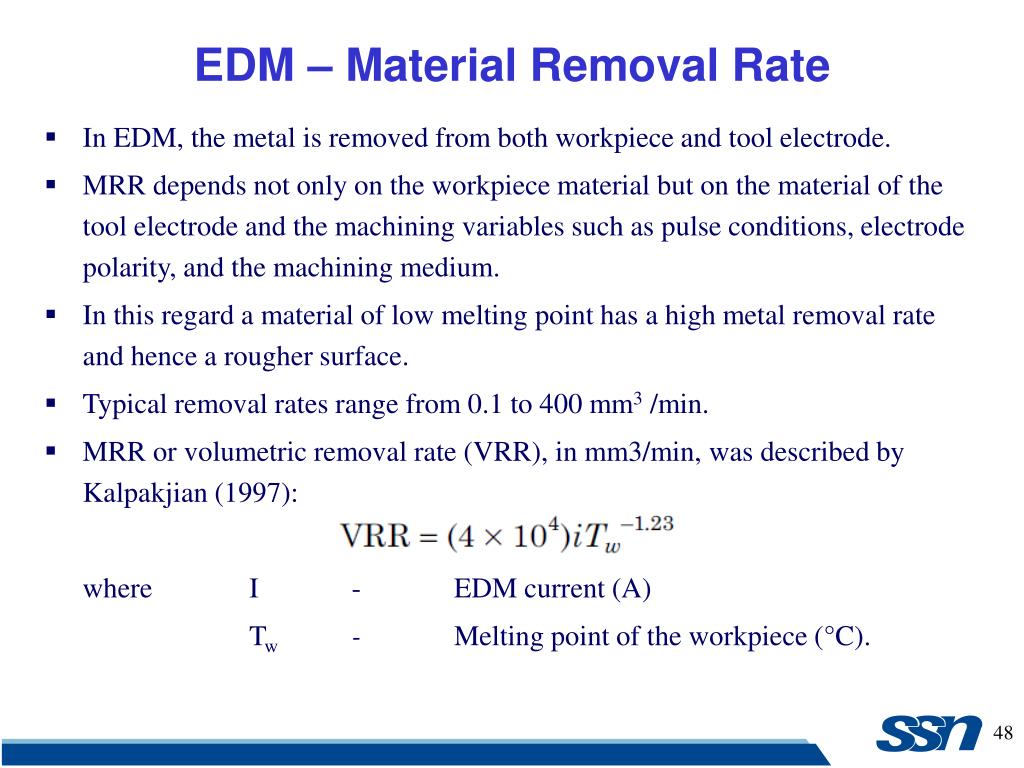

EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics. Electric Discharge Processes Metal removal by a series of discrete electrical discharges sparks causing localized temperatures high enough to melt or vaporize the metal Can be used only on electrically conducting work materials Two main processes. Model of Material Removal During Electric Discharge Machining.

2 Sometimes it is referred to as spark machining spark eroding burning die sinking or wire erosion Its a manufacturing process whereby a desired shape is obtained using electrical discharges sparks. The power supply is given to the EDM process ie. It is a lot like Laser beam Machining but needs a vacuum because it puts of harmful x-rays so is only used by trained personnel Plasma arc cutting is a type of EBM its temp.

Spark occurs within a column of ionized dielectric fluid. Negative terminal is given to the tool and a Positive terminal is given to the workpiece. Two round parts rear are the set of dies for extruding the aluminum piece shown in front 6 Wire EDM.

HISTORY OF EDM In1770s discovered by Joseph Priestly. EDM is mainly used to machine difficult-to- machine materials and high strength temperature resistant alloys. Thesis On Electrical Discharge Machining to stay up all night or a simple task well nail it.

Electrical Discharge Machining Edm Ppt Download

Electrical Discharge Machining Ppt Video Online Download

Ppt Electrical Discharge Machining Edm Powerpoint Presentation Free Download Id 1005127

Electric Discharge Machining Edm Ppt Video Online Download

Ppt Electrical Discharge Machining Edm Powerpoint Presentation Free Download Id 1005127

Ppt Electrical Discharge Machining Edm Powerpoint Presentation Free Download Id 1005127

Electric Discharge Machining In Hindi Youtube

Electrical Discharge Machining

Ppt Electric Discharge Machining Powerpoint Presentation Free Download Id 5371746

Ppt Electrical Discharge Machining Edm Powerpoint Presentation Free Download Id 1005127

Electrical Discharge Machine Edm Ppt Download

Electrical Discharge Machining

Schematic Diagram Of Powder Mixed Electric Discharge Machining Download Scientific Diagram

Electrical Discharge Machining Ppt Video Online Download

Electrical Discharge Machining Edm Pdf Machining Industries

Electric Discharge Machining Edm Ppt Video Online Download